ATB Brushes

OSBORN ATB Brushes

OSBORN

Product Features

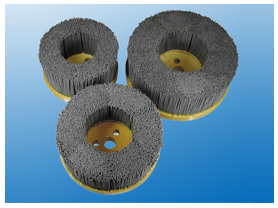

OSBORN ATB disc brushes are manufactured with a proprietary technology to enable high-efficiency deburring. Each disc brush is densely filled with nylon filaments to enable powerful deburring on various workpieces. Usable for deburring of various workpieces including engine parts, gear components, molds, die castings, hydraulic and pneumatic equipment and aluminum wheels. Densely filled with wires for resistance to flattening and breakage, these brushes enable efficient deburring and feature high levels of durability and safety. When used fitted on a machining center, NC milling machine, etc., these brushes improve the efficiency of deburring work conventionally performed manually. Available in outer diameters ranging from 50 to 175 mm and in abrasive grades including #60, 80, 120, 180, 320 and 500 to meet various deburring requirements.

(Each brush should be used with the grip arbor supplied with it.)

Product line-up

Other OSBORN products

About OSBORN

Founded in 1892, OSBORN is a German specialist manufacturer of industrial brushes.

The company has factories in Germany, France, Great Britain, the United States, Spain and other locations around the world. In addition to its proprietary high carbon steel wire, OSBORN uses stainless wire, TY wire, plastic bonded wire, Korfil-E (nylon filaments containing abrasive particles) and other types of wire appropriately for applications to offer products that are durable, safe, and excellent in grinding performance.